pressure vessel thickness testing|pressure vessel inspection checklist pdf : white label Measure the thickness to see if the vessel has changed over time due to use. Analyze the stress to determine if the vessel is still safe for use. Inspect the pressure-release valves to ensure they work correctly. Conduct a . WEB7 de set. de 2012 · Fuente: Región CuscoCon un presupuesto superior a los 52 millones de nuevos soles, ejecutadas por el Proyecto Especial Regional Plan COPESCO. La moderna infr.

{plog:ftitle_list}

WEBCocoa Rampage. $0.33 - $0.60. $0.30 - $1.91. View Skin. Get Best Price. 1 2 3. A searchable list of all green CS2 skins including weapon skins, knife skins, gloves and more.

Measure the thickness to see if the vessel has changed over time due to use. Analyze the stress to determine if the vessel is still safe for use. Inspect the pressure-release valves to ensure they work correctly. Conduct a . When it comes to testing pressure vessel thickness, how do you test the thickness of a pressure vessel? and how to measure thickness? are key questions. Answering them ensures the vessels are safe and work well. Differences Between ASME VIII Div 1 and Div 2. Understanding the differences between ASME Section VIII Division 1 and Division 2 is key. Non-destructive examination (NDE) techniques assess high-pressure vessel designs and equipment for fitness-for-service. Advanced technologies offer many improvements over traditional techniques such as .

hach titralab kf1000 series volumetric karl fischer titrator 3 980 commercial

Vessel Testing Eddyfi Technologies for Vessel Inspection Applications. Ask an Expert. Pressure vessel owners are obligated to ensure their safe use. . Ultrasonic thickness measurement inspection is used to determine the . What are the Different Quality Testing and Inspection of Pressure Vessels? . An ellipsoidal head has a 2:1 change in radius between the major and minor axes, and its shell has matching wall thickness. This head’s tall and light weight makes it ideal for holding high-pressure gases. It can manage pressures higher than 15 bars.construction, inspection, and repair of pressure vessels to be used in the petroleum industry. Entitled APIIASME Code for Unfired Pressure Vessels for Petroleum Liquids and Gases (commonly called the API/ASME Code for Unfired Pressure Vessels or API/ASME Code), the first edition of the code was approved for publication in 1934.Explore pressure vessel wall thickness factors, calculations, standards, examples, and the importance of inspections for safety. . Ultrasonic testing and other non-destructive techniques help identify any areas where corrosion or material degradation has occurred. Based on these findings, engineers can determine if repairs or replacements are .

Theoretically, a spherical pressure vessel has approximately twice the strength of a cylindrical pressure vessel with the same wall thickness, [4] . Hydrostatic test (filled with water) pressure is usually 1.5 times working pressure, but DOT test pressure for scuba cylinders is 5/3 (1.66) times working pressure.

ASME pressure vessel testing is a rigorous process designed to ensure the safety and reliability of pressure vessels in various industries. Compliance with ASME standards, meticulous non-destructive examinations, hydrostatic and pneumatic testing, impact testing (where applicable), and thorough post-test examinations are all essential .6.4.3 For uncoated test specimens, a calibration block of similar material shall be used for calibration. 6.4.4 For Coated test specimens, an appropriate screen range shall be used to accommodate the increase thickness due to the coating plus multiple back wall signals if using the echo-to-echo thickness measurement technique. There are three common hydrostatic testing techniques that are used to test small pressure vessels and cylinders: water jacket method, direct expansion method, and proof testing method. . Check thickness of vessel by ultrasonic instrument periodically. Generally, keep about 15–20% empty space when handling liquids which can generate .

PDF | This Standard is applicable to the structures of pressure vessels as follows: single-layer welded pressure vessels, forged-welded pressure. | Find, read and cite all the research you need .Ultrasonic thickness testing may be useful in detecting thinning areas. General note on pitting - widely scattered pits may be disregarded provided that their depth is no more than one-half of the required thickness of the pressure vessel wall. Areas of concentrated pitting or . The internal (pressure vessel wall) thickness is calculated per 17-5 (b)(1) or (2) – modified flat plate calculations that can be used for any shape of vessel. . External pressure burst testing or finite element analysis could be used to determine a thinner safe vessel thickness than possible using standard code calculations. The burst test .Thickness Test: All unlined cargo tanks transporting material corrosive to the tank, except MC 338: . Test pressure must be maintained for at least 5 minutes. Cargo tanks in liquefied compressed gas service must be externally inspected for leaks during the leakage test. Suitable safeguards must be provided to protect personnel should a .

Thickness measuring is essential across many industries to monitor corrosion, erosion and damage. Ultrasonic thickness measurement (UTM) is commonly used and the method can be applied to a wide range of structures and components that includes ship hulls, piping, pressure vessels and structural steel.

The distinction between thin vs. thick wall pressure vessels is determined by the ratio between the mean radius of the vessel and the thickness of the wall. If this ratio is greater than 10, the vessel is considered a thin wall pressure vessel. If the ratio is less than 10, the vessel is considered a thick wall pressure vessel.above stated parameters computed were based on the API 510, ninth edition (2006), the Pressure Vessel Inspection Code. Table 1. Maximum and Minimum Thickness Readings of all the Investigated Pressure Vessels in the year 2006. Pressure Vessel # Minimum Thickness (mm) Maximum Thickness (mm) Head Shell Head Shell 1 8.800 8.400 9.20 0 9.40 0%PDF-1.7 %µµµµ 1 0 obj >/Metadata 903 0 R/ViewerPreferences 904 0 R>> endobj 2 0 obj > endobj 3 0 obj >/XObject >/Font >/ProcSet[/PDF/Text/ImageB/ImageC/ImageI .

It is essential to determine the optimal pressure vessel's shape, thickness, and dimensions to satisfy particular application requirements and retain structural integrity while in use. Rewarding Techniques: The ability of the pressure vessel to endure internal and external forces is improved by using the proper reinforcing techniques, such as .

The most common method for calculating pressure vessel thickness is using the Barlow’s Formula:. t = (P * D) / (2 * S * E – 0.6 * P) Where: t is the required thickness of the vessel wall.; P is the internal pressure.; D is the inside diameter of the vessel.; S is the maximum allowable stress for the material.; E is the joint efficiency, accounting for factors like welding quality. What is the minimum thickness of pressure vessel ASME? The minimum thickness of a pressure vessel according to ASME Code depends on the design pressure, allowable stress, material properties, and other factors specified in the applicable ASME section. . AS1210 is an Australian standard for the design, fabrication, inspection, and testing of .

Applications of Pressure Vessel. Pressure Vessels are most widely used in the following sectors. Refinery and Petro-chemical; Fertilizer; Oil and Gas; Chemical; Power Plants; Regular inspection of pressure vessels is very important to avoid pressure vessel failures. API 510 provides guidelines for pressure vessel inspection. Categories of welded joints in a pressure vessel ... 45 Figure 9. . HYDRO TESTING AND PNEUMATIC TESTING . In conjunction with specifying the vessel thickness,Pressure vessels are subject to stringent regulations to ensure their safe operation. Our team at Red River is well-versed in these regulations, including those set by the ASME Boiler and Pressure Vessel Code and API standards. We understand the complexities of compliance and work diligently to meet or exceed these requirements in every pressure vessel we manufacture.PRESSURE VESSELS David Roylance Department of Materials Science and Engineering Massachusetts Institute of Technology Cambridge, MA 02139 August 23, 2001 Introduction . Consider now a simple spherical vessel of radiusr and wall thickness b, such as a round balloon. An internal pressurepinduces equal biaxial tangential tensile stresses in the .

construction, inspection, and repair of pressure vessels to be used in the petroleum industry. Entitled APIIASME Code for Unfired Pressure Vessels for Petroleum Liquids and Gases (commonly called the API/ASME Code for Unfired Pressure Vessels or API/ASME Code), the first edition of the code was approved for publication in 1934.Test Lab Data JRS . In severe cases of corrosion, the vessel thickness may have decreased below the minimum wall thickness necessary for the MAWP stamped on the vessel. Under those circumstances, the MAWP can be decreased to a point that is supported by the remaining wall thickness, but in most cases the vessel is removed from service until .

hanna instruments hi 903 karl fischer volumetric titrator commercial

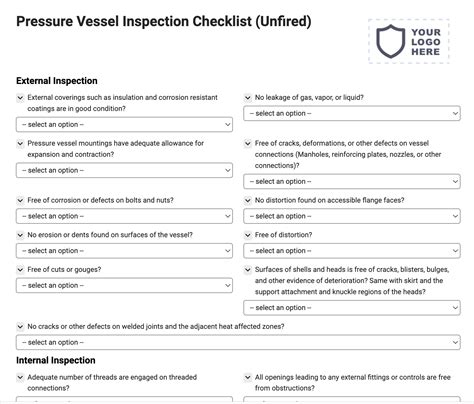

pressure vessel repair checklist

hi 903 karl fischer volumetric titrator commercial

pressure vessel inspection sheet

pressure vessel inspection requirements

Resultado da TALA PNEUS ITAPEVA LTDA Nome Fantasia: TALA PNEUS Natureza Jurídica: 206-2 Sociedade Empresária Limitada CNPJ: 23.190.927/0001-37 Início das atividades: 01/09/2015 Tipo: Matriz Situação: Ativa Atividade principal: 45.30-7-03 Comércio A Varejo de Peças e Acessórios Novos .

pressure vessel thickness testing|pressure vessel inspection checklist pdf